EDGING

PVC Edging

PVC Edging

Thermoplastic PVC (Polyvinyl Chloride Plastic) edge banding is manufactured through an extrusion process into many different thicknesses and widths to match solid colors, patterns and wood grains of plastic laminate. PVC edging adds a smooth, durable edge surface for panels, tables and other case goods.

Vinyl T Edge

Vinyl T Edge

T edging is a durable plastic band that is inserted on the edge of a panel. The T molding is a high quality extruded molding that has a solid color throughout. The face of the T edge is available in different thicknesses and profiles. The back of the T edge has a ribbed barb that is inserted into a kerf in the panel so it is seated firmly.

Plastic Laminate Edge

Plastic Laminate Edge

Laminates are available in hundreds of colors, patterns and wood grains. Plastic laminate is made from layers of resin-impregnated kraft paper, topped with a decorative melamine surface, and then pressed into sheets under extreme pressure and heat. Plastic laminate is one of the most durable, beautiful and easy to care for materials.

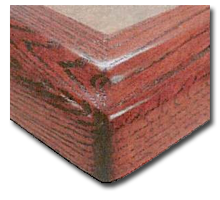

Wood Edge

Solid wood edges are available in different thicknesses and profiles. Our standard species of wood used are oak and maple, both are hardwoods which are more dense and durable. Maple wood has a tight grain with a fine texture, unusually straight. Maple has a creamy white color often tinged with pink or pale reddish brown tones. Oak wood has a straight grain with a course texture. Oak wood ranges from white to light brown in color with golden, reddish tones.